BeeInventor’s IoT Research: Quantifying the Impact of IoT Construction with Real World Case Studies

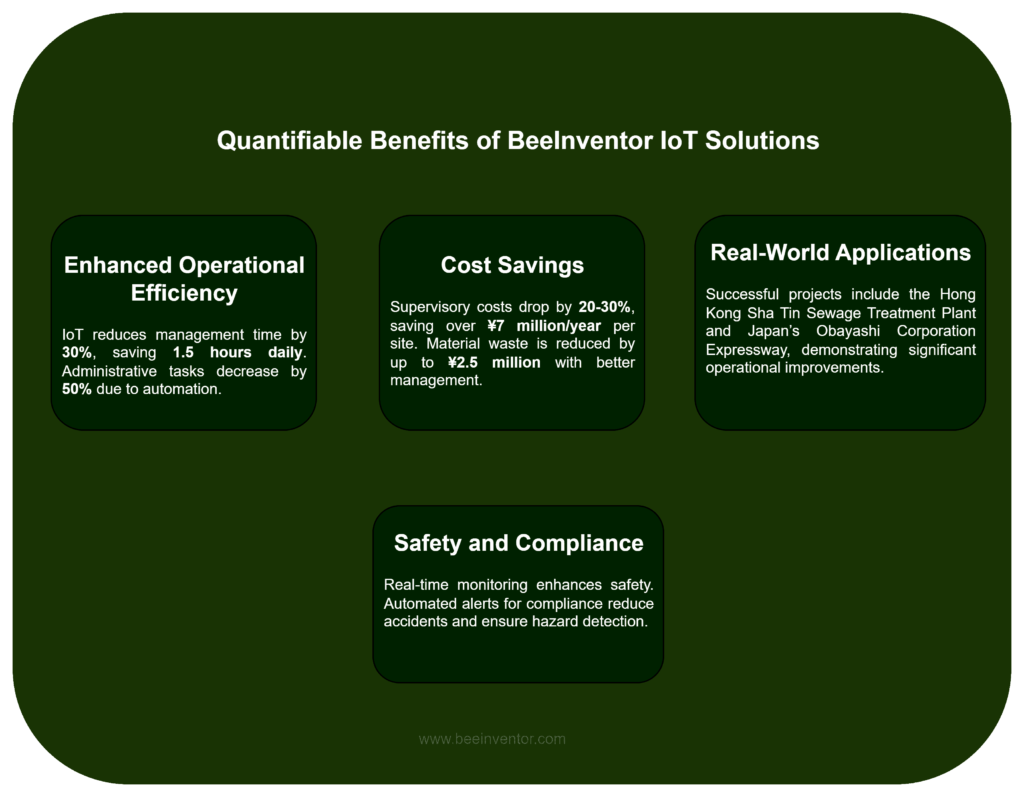

1. Enhanced Operational Efficiency

IoT technology significantly improves efficiency on construction sites by reducing management time and administrative workloads.

- Reduction in On-Site Management Time:

IoT solutions can cut on-site management time by up to 30%, saving approximately 1.5 hours per day for supervisors.- Current Scenario: Supervisors typically spend 8 hours a day on tasks like site patrols, safety checks, progress monitoring, and meetings—5 of which are spent on patrols and inspections.

- With IoT: Remote monitoring and automated data collection reduce patrol times by 30–50%, saving 1.5 hours daily.

- Reduction in Administrative Workload:

Administrative tasks such as daily reports, labor management, safety records, and material tracking consume 2–3 hours daily.- With IoT: Digital platforms automate data entry and reporting, reducing administrative workload by over 50% (saving 2 hours daily or 40 hours monthly for a 20-day work month).

2. Cost Savings

IoT adoption leads to significant cost reductions in both personnel expenses and material waste management.

- Reduction in Supervisory Personnel Costs:

By optimizing site supervision through remote monitoring, companies can reduce supervisory personnel costs by 20–30%, amounting to annual savings of over ¥7 million per site.- Current Scenario: Supervisors earn an average annual salary (including benefits) of ¥6–8 million, with two to three supervisors typically assigned per site.

- With IoT: Remote monitoring reduces the need for on-site supervisors. For example, a three-supervisor team can be reduced to two, saving ¥7 million annually.

- Reduction in Material Waste:

Material losses (due to theft, misplacement, or overordering) account for 1–5% of total material costs in construction projects.- Current Scenario: For a project with an annual material cost of ¥100 million, losses range from ¥1–5 million.

- With IoT: Smart locks and GPS tracking reduce material waste by 30–50%, saving up to ¥2.5 million annually for projects with ¥5 million in material losses.

How IoT Works to Achieve These Benefits?

1. Remote Monitoring

IoT devices enable supervisors to monitor multiple sites remotely using real-time data from connected sensors and cameras. This reduces the need for physical presence while ensuring oversight.

2. Automated Data Collection

IoT sensors automatically collect data on progress, safety compliance, and resource usage. This eliminates manual record-keeping tasks and ensures accuracy.

3. Smart Material Management

IoT-enabled smart locks and GPS trackers help prevent theft or misplacement of materials while optimizing inventory levels to avoid overstocking or shortages.

Real-World Applications

BeeInventor’s IoT solutions have been successfully implemented in various projects across Asia:

- The Hong Kong Sha Tin Sewage Treatment Plant Relocation project utilized IoT to streamline operations and reduce costs.

- Japan’s Obayashi Corporation Expressway project leveraged IoT for better resource management and improved productivity.

These examples highlight how IoT technology can deliver tangible benefits across different types of construction projects.

How BeeInventor Can Help You Transition to IoT

At BeeInventor, we provide comprehensive IoT solutions tailored specifically for the construction industry:

- Deployment of advanced sensors for real-time monitoring.

- Integration of AI-powered analytics for better decision-making.

- Implementation of digital platforms to streamline workflows.

- Ongoing support and training to ensure seamless adoption.

Our solutions are designed to help you reduce costs, improve efficiency, and future-proof your business against industry challenges.

References:

[1] 国土交通省「建設現場の生産性向上に関する調査報告書」(2022): 現場管理時間短縮および事務作業効率化に関するデータ。

[2] 厚生労働省「建設業の労働実態調査」(2023): 人件費削減に関するデータ。

[3] 建設ITワールド「建設業のデジタル化における業務効率化の事例」(2023): デジタルプラットフォーム導入による効率化事例。

[4] 経済産業省「建設業のIoT活用によるコスト削減効果レポート」(2022): 資材ロス防止およびコスト削減効果に関するデータ。